On commercial embroidery machines, the angle of the needle and its needle eye is very important. How important?

While a specific degree angle isn’t a universal standard for all commercial embroidery machines, the correct positioning of the needle is crucial. The goal is to align the needle’s parts with the machine’s rotary hook mechanism to ensure each stitch is formed properly.

Buy needles here:

Bobine Case and needles

The Importance of Needle Alignment

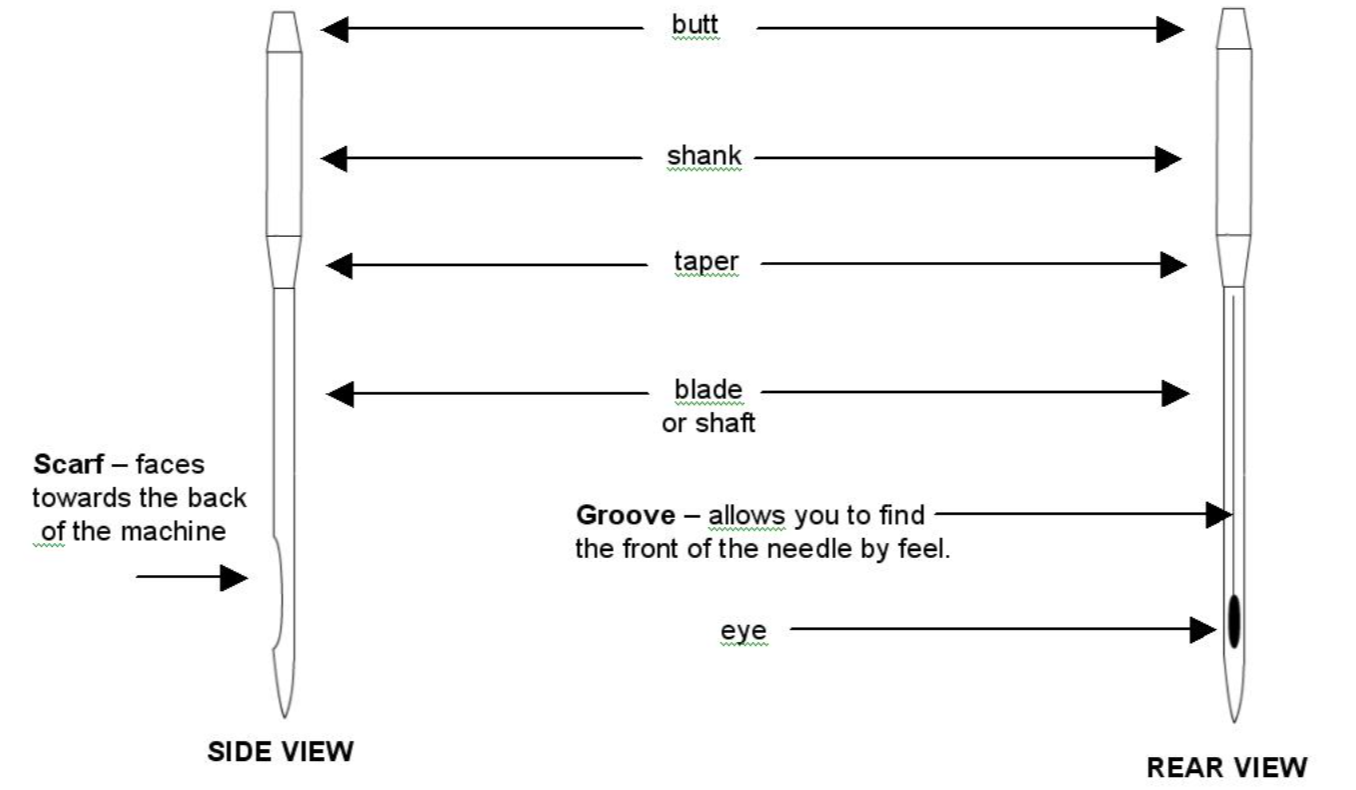

The needle’s scarf—a small indentation on the back—must be precisely aligned to the rotary hook. As the needle rises after reaching its lowest point, the rotary hook’s point must pass directly through the loop of thread created by the scarf. If the needle is not aligned correctly, the hook will miss the loop, resulting in skipped stitches and thread breaks.

To prevent this, commercial embroidery machines typically use round-shank needles that are designed to be inserted with the long groove facing the front and the scarf facing the back. Because a slight rotation can throw off the machine’s timing, technicians and operators often use specialized tools, such as a needle setter, to ensure perfect alignment.

Read more more about the angle:

The angle of the needle eye is important because it is designed to work with the bobbin hook to create a stitch. The scarf, which is the indentation above the eye on the back of the needle, provides a space for the hook to grab the upper thread and loop it with the bobbin thread. If the needle is not inserted correctly, the eye and scarf will be misaligned, leading to skipped stitches and thread breaks.

For home embroidery machines with a flat-sided shank, the flat side should always face the back of the machine. For commercial machines with a round shank, the long groove should face the front. It is also important to ensure the needle eye is not bent or damaged, as this can also cause issues.